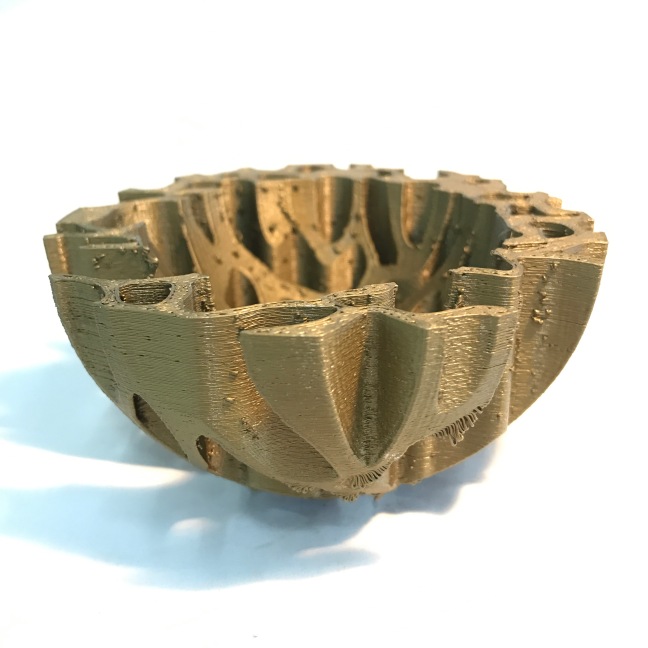

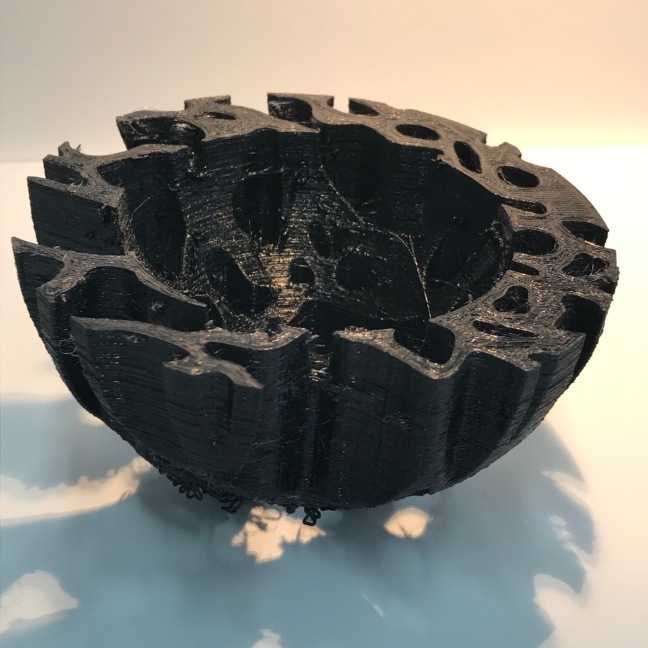

The first of my new filaments I tested was the carbon fibre and I printed this on my home M3D printer. It printed very easily and the support material was very easy to remove. The finished material gave very fine lines and felt quite strong.

I sanded down the top surface to see what the material would look like polished up. I was really happy with the finish. It gave a great shine.

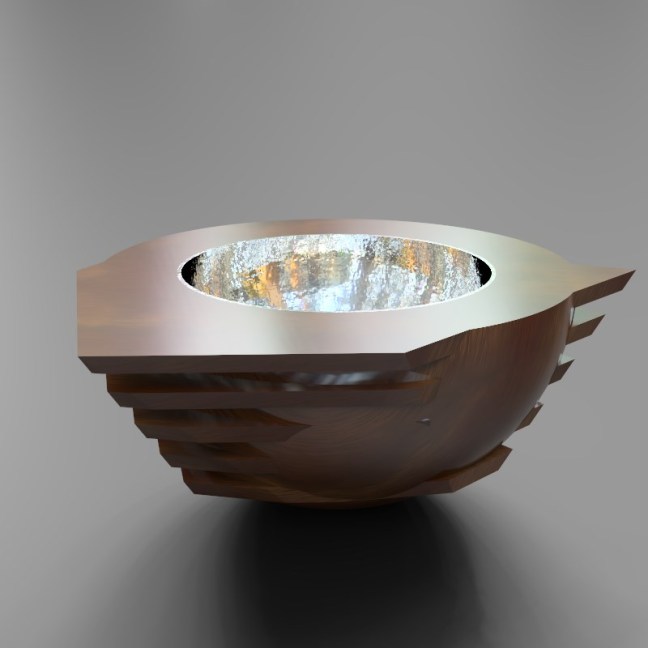

I decided that for this piece I would hand raise the other sections of the bowl using my 3D printed hammers.

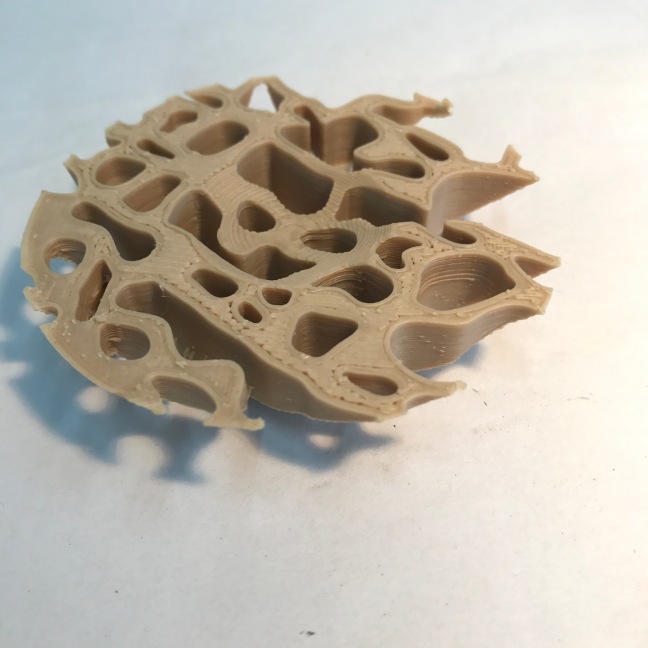

I used my laser sintered hammer initially to planish the bowl. Unfortunately this broke very soon in to the process. The internal section looked very powdery due to the two part green process that Shapeways use. I think this makes the metal much weaker. I am going to try and reprint this on the direct steel sintering machine in Aberdeen and see if that makes any difference.

I raised a smaller inside bowl to the piece in the same way. However I had to use a regular planishing hammer to finish off both. I must confess however that as the inside bowl was so small and fiddly I hand raised it to a certain point and then used the larger doming punch in the department to get the final shape.

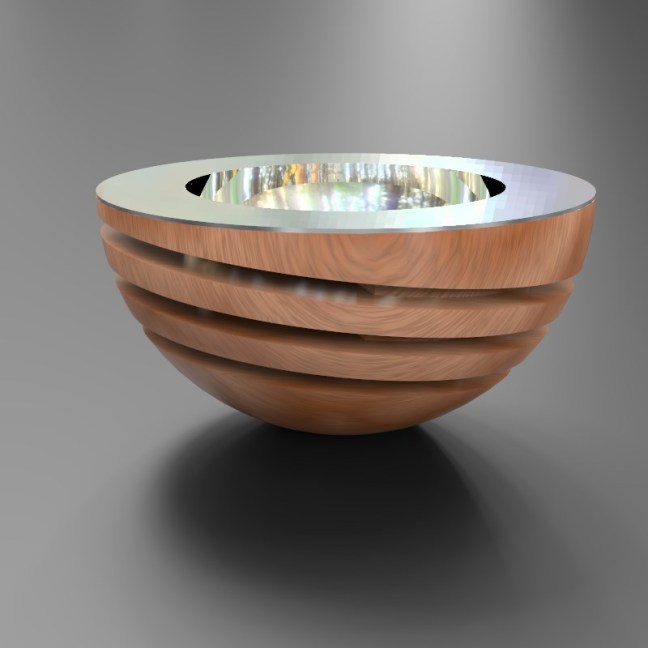

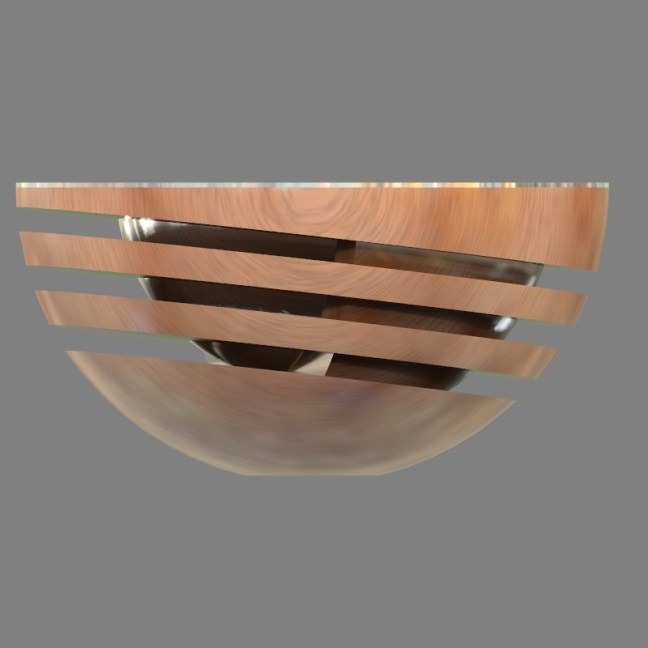

I decided I liked the contrast of copper and black and oxidised the inside of the larger bowl and outside of the smaller. I used a two part resin and mixed this in to the bowl. I am regretting not testing this first as it seemed to react. I am hoping that it will dry enough to sand back and make it look good but if this doesn’t work I will have to re-make it and test another type of resin. The other reason it may have reacted like this would be if there had been some moisture in the bowl before I added the resin.