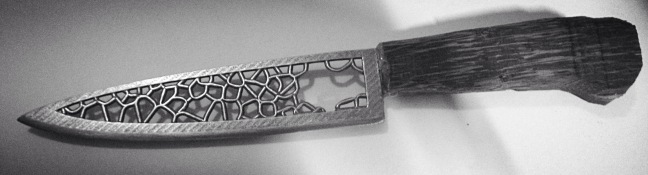

One of the main tools I need in my kitchen would be knives. This is the second knife I worked on. For this I designed the knife in CAD and 3D printed the blade in steel. The cost of a solid knife was far too expensive to justify 3D printing, so I decided to cut out most of the weight from the middle of the knife.

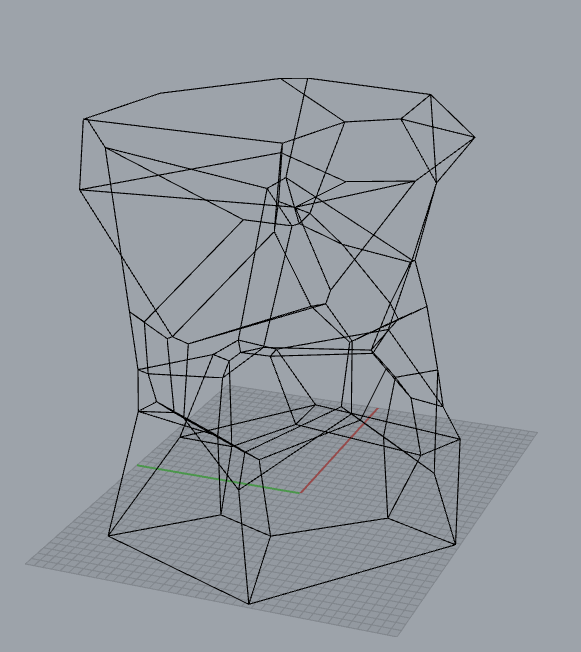

I then used algorithms in grasshopper to put back in place a structure to give more strength to the piece. Using grasshopper allowed me to play with the structure until I found an arrangement I was happy with. This was great in this particular case as if I had drawn this in rhino alone I would have only had the option I had drawn and it would have been far more difficult to change.

The knife cost £34.15 to print from Shapeways.

The first job I had was to sharpen the blade. I didn’t want to temper the steel so I avoided using a machine to grind the edges. At first I used a file which took off most of the edge. I was then given a sharpening stone from a friend which was far easier for the job and took very little time.

The next job I had was to make the handle. I wanted a contrast in the piece between handmade and CAD build work as I felt this would add part of my soul into the work more with combining the handmade element.

I cut a piece of metal to act as a stopper at the end of the handle. This slipped down to join between the handle and the blade to make the piece look a bit neater. I then made the handle using a piece of exotic hard wood called black plamera. I cut the wood in half and cut out the shape of the handle. In the centre of the piece I placed some dark blue acrylic sandwiched between light gathering plastic so that when you hold it up to the light you can see through the piece.

After gluing the handle together with epoxy resin I glued two brass rods though the handle to secure.

I then filed the handle into shape and sanded down to a high finish. I used Danish oil to finish the wood to a high polish.